THE PERFECT CIRCLE FOR CONVENTIONAL MILKING

AirWash 30 (AW30) is the most flexible and affordable automated dip and rinse system for your parlor available on the market in this area. Automatic teat dipping, milking cluster disinfection and rinsing with clean tap water is safe, quick and easy! All this is possible without having to purchase special milk liners, teat cups or milking cluster.

The fact is that automation reduces the likelihood of human error and reducing labor and inefficiencies provides more consistency in the milking process. The combination of these advantages, all evident in the revolutionary AW30 system, automatic dipping and backflushing system can improve the milk quality in your herd and have a positive influence, which is the foundation of your dairy farm. The revolutionary AW30 can increase the health of the herd.

Leave nothing to chance! Thanks to the AW30, you can:

- gain efficiency by reducing workload or achieving faster parlor throughput

- reduce the risk of one sick cow infecting the entire herd and thus minimize the risk of mastitis.

- minimize stress and unrest by simplifying and standardizing your work process.

RELIABLE MILKING, DIP AND BACKFLUSHING WITH AW30

Discover the ultimate Dip and disinfection technology … AW30 automates two important, time-consuming work steps at the end of the milking process:

- Reliable and accurate dipping of the teats after milking,

- Effective disinfection of the entire claw after each individual milking process … and thus improve udder health with great care:

Eliminates over 98% of the organisms

Automatic teat care with a backflush function eliminate over 98% of the organisms that can infect the next cow with potential germs: milking, dipping and sanitizing in a single pass! This means significantly less downtime and treatment costs.

AUTOMATIC DIPPING –

ACCURATELY AND SAFELY

Dip application in the best way: AW30 covers the teats at the best time. Dipping directly into the teat cup is accurate. AirWashPlus automatically always ensures outstanding consistent dipping quality and thus full protection around the milk-canal and teats!

OPTIMAL TIME, OPTIMAL AMOUNT, OPTIMAL PROTECTION

The teat is dipped at the best time with the optimal amount of dip. The teat is treated while it is limp and stretched by the vacuum. This optimizes the dip application. It can penetrate deep into the skin to ensure complete protection of each teat before the cluster is removed.

AUTOMATED DIPPING AND RINSING RESULTS IN EFFICIENCY GAINS

You can rely on the consistent of the dip procedure. Automatic dipping replaces the manual constant repetitive

movements during dipping and / or spraying at the end of the milking process. This improves the working routine, provides room for proper udder preparation and makes the milking parlor more efficient that results in higher throughput.

SAVING DIP CONSUMPTION, LOW

OPERATING COSTS

The dip applied is always fresh and uncontaminated. The dip amount is adjustable and can be precisely controlled. This unique working method ensures minimal dip consumption and consistent application so that AW30 always works economically.

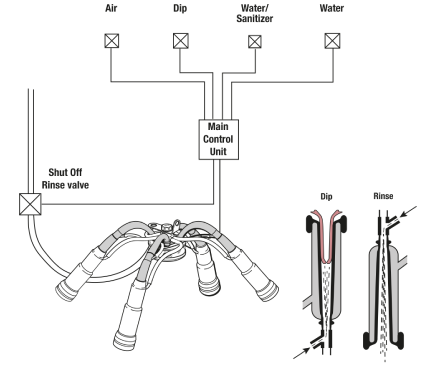

THE TEAT CUP LINER DIP PROCESS, HOW DOES IT WORK?

1. The teat is dipped by spraying the dip spray from the short milk hose onto the bottom of the teat.

2. Even distribution due to the patented AW30 injector.

3. The milk duct is shielded before it is exposed to the environment.

REDUCTION OF INFECTIOUS ORGANISMS

Automatic backflushing and disinfection of the milking cluster: the AW30 System does not give pathogens a chance.

COMPLETE RINSING BEFORE THE NEXT COW

An intensive rinsing process is

completed before the next milking

session, removing any residual

dip in the cluster, disinfecting

and rinsing with clean water while

waiting for the next cow.

Saves dip consumption

A CLEAN AND HEALTHY PLACE

The entire milking cluster is effectively cleaned for the next cow. This kills infectious organisms that reside in the milk liner, bowl and long milk hose of the milking unit to reduce the chance of mastitis spreading through milking equipment. Alternating water cycles are blown out with powerful blasts of air, creating turbulence in the cluster and reducing the amount of water required to effectively flush the unit.

THE KEY TO MILK QUALITY

Because it is possible to rinse the whole thing with clean water and blow dry the milk liners by means of a long blast of air, the milk and the disinfecting media are carefully separated from each other.

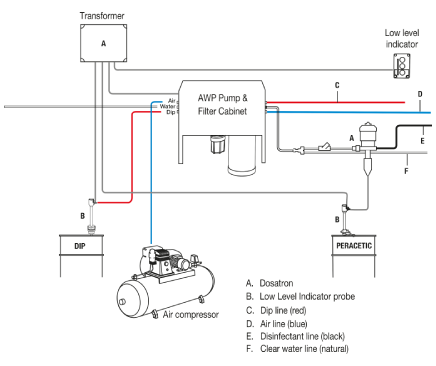

Operational safety is constantly under control, the AW30 Control Unit (main control) monitors system pressures and chemical levels and alerts the user if there is a problem that could be affecting proper operation. You always have your finger on the pulse to ensure consistent system performance.

IS THE AW30 SYSTEM SUITABLE FOR YOUR FARM? SURE!

Whether rotary parlor, side by side, open tandem, herringbone and swing-over parlor: Thanks to AW30, the operator can concentrate on other tasks that can improve milking and udder health. The AW30 System with its revolutionary Dip and BackFlush technology is the right choice for any parlor and is the start of profitable milk production.

AW30 FEATURES

- Applicable in every type / brand of milking parlour

- Hygienic liners for each individual cow

- Reduction in the spread of contagious mastitis

- Saves dip consumption

- Dip application in the best way

- Fully automatic operation

- Minimum use of cold or hot water

- No disturbance of normal milking routines

- Flexible and affordable

THE AW30 SYSTEM HAS THREE VERSIONS

The uniqueness of AW30 is not only that the dairy farmer can continue to use the “existing” milk liner and cluster, but because countries and / or authorities apply different regulations, we can, as it were, “custom-made” the AW30 System. Available in 3 different versions:

1. AW30-Regular

2. AW30-Pro

3. AW30 Gold

AW30-REGULAR

The teat is sprayed by a patented injector located in the short milk hose. The cluster is removed and is in the normal park position. Disinfection on the inside of the milk liners can now take place by means of the so-called backflush function. Alternating cycles with a mix of water / disinfectant and air rinse the dip agent out of the milk liner and also has a disinfecting effect! These alternating cycles can be easily adapted to suit everyone’s needs.

AW30-PRO

The treatment of the teats is the same as in the AW30-Regular variant described above. With AW30-Pro, the long milk hose is closed as soon as the ACR is activated, rinsing and disinfection now takes place not only on the inside of the milk liner, but also through the long milk hose, so that the entire milking cluster is disinfected and rinsed clean on the inside. The milking cluster is in the lowest position during this phase of the flushing, this is possible because the decrease signal is interrupted, causing the milking cluster to lower by gravity. When the rinsing process is complete, the detachment is reactivated and the long milk hose unblocked so that the milking cluster returns to the normal park position. All of this is controlled by the individual AW30-Pro controller.

AW30-GOLD

This variant of the dip and rinsing process is identical to the AW30 – Pro variant described above, but in order to exclude any form of residue, the whole is rinsed with clean tap water at the end, reducing the risk of residues to a minimum is limited.

AW30 SYSTEM IS VARIABLE AND FLEXIBLE

Not only the amount of dip, water and air can be perfectly adjusted to the wishes of the customer, but it is also possible to “upgrade” the system at a later stage from a Regular to a Pro or Gold version.